There’s nothing more valuable than turning loads of waste into tons of nutritious material for a garden or lawn. Commercial composting helps that happen at scale.

What is commercial composting?

Commercial composting (aka industrial composting or large-scale composting) is one of the most beneficial recycling methods that can convert millions of metric tons of food waste into useful compost. This is a growing service in many areas offered by private companies or by municipalities in some places.

Just as with home composting, industrial composting isn’t just food, which is typically green material. It also adds in leaves, grass clippings, and other carbon-rich brown materials.

We’ve covered a lot of articles on composting, the benefits of composting, and different methods of composting. But today, our primary focus will be on commercial (large-scale) composting.

Let’s see what commercial composting is, how commercial composting works, and how we can make commercial compost using different methods.

What Is Commercial Composting?

First of all, let me give you a brief introduction to composting.

Composting is a technique that naturally converts organic material such as food waste, yard waste, and more into a nutrient-rich material through natural processes. It has many benefits, including reducing emissions, reducing landfill waste, and much more.

Easy and simple! You guys might already know there are two major types of composting—aerobic and anaerobic.

All composting methods involve the decomposition of organic waste in the presence or absence of oxygen. Although anaerobic breakdown is more suitable for commercial or industrial composting in large volumes, you can carry it out in both ways.

Commercial composting can be explained as a composting process followed by a commercial or industrial company to collect and process massive amounts of compostable wastes. It then uses different methods to decompose that waste on a large scale. This is done in combination with waste disposal and recycling programs to minimize landfill waste and reuse materials. The compost produced is then sold to farmers and gardeners (in some areas, a portion is even given to them.)

The finalized compost is sold to farmers and gardeners for gardening and landscaping. Some municipalities will even give it away to residents or participants.

How Does Commercial Composting Work?

Now that you know what commercial composting is let’s see how it works.

The process involved in commercial composting is similar to household composting; the difference comes in the degree and maintenance (I’ve covered the difference between commercial composting and home composting further in the article.) Industrial composting allows techniques that aren’t practical for a home composting system. It’s done at a much larger scale but it uses many of the same basic principles and has the same benefits.

The process involves:

- The collecting of bio compostable wastes from different sources around the city.

- These sources include household waste from kitchens, lawns, or gardens; agricultural waste from agricultural operation sites like farms; food-processing units like hotels, restaurants, cafes, and groceries stores; commercial waste streams consisting of materials like paper and cardboard, wood, rubber, textile, and bio-wastes.

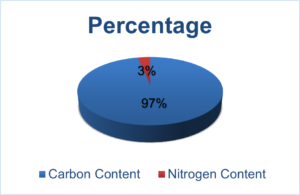

- However, while making the compost from the above-mentioned brown and green wastes, the ideal Carbon to Nitrogen (C/N) content ratio should be 30:1. Industrial composting operations, working at scale, need to be more scientific than our home composting operations. There we recommend a less scientific but very effective method of maintaining your carbon-to-nitrogen ratio.

- Large-scale municipal composting facilities collect these wastes from garbage collection and recycling agencies.

You might have seen distinct green waste bins for collecting yard trimmings and garden waste. Compostable and biodegradable organic material is managed separately from other trash.

Some industrial composting facilities also allow individuals to leave compostable materials at the composting sites.

- Once the compostable brown and green waste is collected, it is processed to remove any large non-compostable materials.

- After that, both green (nitrogen-containing) and brown wastes (carbon-containing) are mixed separately, moisturized, and turned into “sludge.”

- After that, both green and brown content is mixed in the proper ratio at composting sites, where under-maintained conditions of pH, temperature, and moisture, the composting material is converted into premium compost.

The conversion of wastes into compost is carried out using different approaches. Let me discuss some methods of commercial composting with you.

Commercial Composting Methods

Here are some of the most valuable methods used to produce commercial compost.

Vermicomposting

Vermicomposting involves taking help from worms.

Although vermicomposting is mainly used for making household or farm compost on a small-scale basis, it can also produce high compost yields commercially.

The process involves the breakdown of green and brown waste like food scraps, yard trimmings, dry leaves, hay, straw, coffee grounds, paper, and bio-waste.

Earthworms or red worms are the main entities used to form vermiculture. Combining vermiculture with other composting systems can result in the formation of more stable compost.

What’s vermiculture? Vermiculture is the first step in making vermicompost. It is the artificial breeding of earthworms in controlled conditions.

- Making vermiculture involves nurturing the worms in containers filled with cow dung, garden soil, hay, leaves, and shredded paper.

- Ensure you keep the moisture levels up to 45–55% because worms need a humid environment to respire.

- Aeration levels must meet 50% levels.

- The optimum temperate and pH of the mixture should be 20°C–30°C and 7.5, respectively.

Making Vermicompost

Before you start the process, you should keep the investment in mind—both one-time and annual investments for sheds, vermi-beds, land, building, and transport.

The process involves:

- Once the vermiculture is formed, it is introduced into the vermicompost containers to produce enriched compost.

- Worms feed on 25–35% of their body weight of organic matter, provided proper conditions.

- Provide the worms with layers of feedstock. These layers should not exceed 1 inch in depth.

- The worms start digesting the brown and green waste and produce worm castings.

- These worm castings are harvested every few months and dried in the open air to form vermicompost.

Now, let’s head toward other methods of commercial composting.

Windrow Composting

Windrow composting is one of the most extensively used methods of commercial composting. In this method of commercial composting, the biodegradable wastes are arranged in the form of piles that are 4–8 feet high and 14–15 feet in width, settled next to each other.

These rows of organic wastes are called “windrows.”

The process is primarily aerobic and involves high-temperature composting with proper aeration via turning with heavy-duty equipment.

However, as it requires such a large area, it is also suitable for anaerobic composting.

Process of Making Compost

As far as the ingredients are concerned, one can compost all types of green and brown wastes using this method.

- This method turns food scraps, yard trimmings, animal manure, biodegradable plastics, paper products, and fish products into compost.

- There are two phases involved in the process:

- In the active phase, the bulk of bio compostable wastes is settled as piles in the form of rows. These piles are then provided with water, and microbes dwell and start degrading the material. This, in turn, increases the temperature of the piles up to 60°C.

- On the other hand, once the temperature and moisture levels are maintained (mostly, it takes a month), the piles are mechanically aerated using compost turners. This tuning process is repeated every month to ensure proper aeration. This is called the curing phase.

- Compost is then processed and filtered using compost processors into equal-sized components.

Finally, the compost is ready.

That was all about turned window method of composting. Now, let’s take a look at static piles of compost!

Static Pile Composting

The aerated static pile (ASP) composting, aka the Beltsville method, is considered one of the most premium methods of commercial composting. It is essentially an effortless process and can be done from small-scale micro bins to a larger scale of piles aerated with perforated pipings.

Aerated static pile composting is a hands-off operation for making profitable compost. The method involves automated aeration of compostable piles of waste. Thus, it doesn’t require manual turning.

The Process

In static pile composting, you will make piles of compostable material consisting of 3 layers:

- Plenum Layer.

- Organic waste.

- Insulation layer.

- These three layers are aerated using blowers and pipelines.

- The plenum layer is a layer of mulch or wood chips applied above the pipelines so that air can diffuse out to the composting material present above.

- Above the plenum layer is our biodegradable waste material in the form of piles.

- And at the top, there is an insulating layer. You can use composting covers (made up of an ePTFE semi-permeable membrane) or a layer of mulch or finished compost.

- All these layers help maintain the aeration, temperature (up to 140°F), and pile moisture.

- That’s the setup, including the aerating system comprising of fans, blowers, and perforated ducts.

- The aeration is maintained either by pushing or pulling air through the pile.

- It is one of the fastest methods of making compost—within 3–6 months.

In-Vessel Composting

The final method in today’s list is In-vessel commercial composting. In-vessel composting is an industrial method of making higher quality compost and is the only method in today’s article that is both aerobic and anaerobic in nature.

It is especially important because it doesn’t take as much space as other methods like windrow or static pile composting.

In-vessel composting involve the breakdown of organic matter in an essentially closed environment, for example, inside drums, concrete-lined trenches, silos, or cylinders.

Making of the Compost

Here’s the process:

- If the conditions of proper aerations are maintained, the aerobic breakdown of the waste will occur.

- The aerobic microbes would carry out the process of aerobic breakdown and increase the compost temperature to about 60°C, enough to kill all harmful contaminants.

- Moreover, critical conditions like proper aeration and moisture levels are controlled either mechanically or electrically.

- If the conditions are anaerobic, it will take longer to finalize the compost produced.

- The fermentation in anaerobic conditions caused by anaerobic microbes does not necessarily increase the temperature much. Instead, in the digesters, the pH of the mixture is quite acidic, which would kill all the harmful microorganisms in the compost.

- However, you’ll have to keep your compost for about a year in that acidic environment to ensure the product’s safety.

- After that, you’ll also need to aerate the anaerobic compost for a month before using that for crops or landscapes.

Now, let’s talk about some issues you can face during the industrial formation of compost.

Compost Issues With Commercial Composting

No matter what type or method of municipal composting we are talking about, there’s always a chance of contamination.

The primary source of contamination is non-biodegradable garbage.

- Whenever a commercial composting facility collects material for composting or is provided with the material, there is always some junk that can’t be decomposed.

- It is crucial to separate the decomposable and the non-biodegradable waste to ensure compost quality.

The other problem is plant toxins.

- One of the most dangerous herbicides that might contaminate your compostable material is Clopyralid, usually found in city-manufactured compost. Not only that, but commercially prepared compost could also contain a wide range of pesticides, herbicides, fungicides, and harmful pathogens.

Therefore, maintaining proper temperature conditions (up to 140°F for at least three days) and pH (5.5 to 8) are essential to remove all kinds of toxins.

- Composting biodegradable wastes produce many by-products, including gases like CO2 and Methane and a liquid known as Leachate. These contaminants need proper disposal; otherwise, they can pollute water channels and air.

What’s the difference between commercial composting and home composting?

Commercial Composting vs. Home Composting

The main difference between commercial composting and home composting is maintenance. Essentially, both home composting and commercial composting are the same processes in which the biodegradable wastes are decomposed and turned into nutritious compost that can be used for gardening and landscaping. Commercial composting does it at a much different scale and with different equipment.

But some subtle differences must be considered:

- Household composting is primarily aerobic in nature. The aerobic breakdown is preferred to prevent foul odors. On the other hand, valuable commercial compost is also produced anaerobically.

- If we talk about home composting, it involves the breakdown of household wastes such as food scraps, yard trimmings, leaves, tea bags, coffee grounds, hair, fur, paper, wood, egg shells, etc.

- Household composting can’t decompose animal manure, bio-solids, bio-degradable plastics, dairy products, meat, oils, or fish products, while commercial composting can.

- Moreover, professional maintenance of proper conditions like aeration, temperature, moisture levels, and pH are challenging at home, while in commercial composting facilities, all of these measures are professionally controlled.

- Home composting is much more economical than commercial composting.

Home composting includes the use of:

- Compost heaps or piles.

- Compost tumbler.

- Trench or pit method.

- Compost bins.

- Vermicomposting.

- Bokashi method.

Cost of Commercial Composting

So, what’s the cost of commercial composting?

It’s evident that the capital cost would differ for different methods because they involve different extents of investment.

- Vermicomposting is fairly economical. Manufacturing 1 ton of vermicompost would cost around $20–$30.

- In windrow composting, the capital will be much higher. Making compost using turners and tractors would require $29,200 of annual investment.

- In static pile composting, you won’t need any turner or aerator, but a whole ASP system can be managed for $15,000 for 10,000 tons of compost production per year.

- And lastly, In-vessel composting is one of the most expensive methods. The capital cost for manufacturing around 2,700 tons of finished compost per year would cost capital of $2,800,000.

Final Words

More and more cities and providers are starting to offer commercial composting. It has huge benefits for the community and can be a profit center too. It’s a way of turning some of our household waste into a sustainable system reducing pollution and waste.